Molding

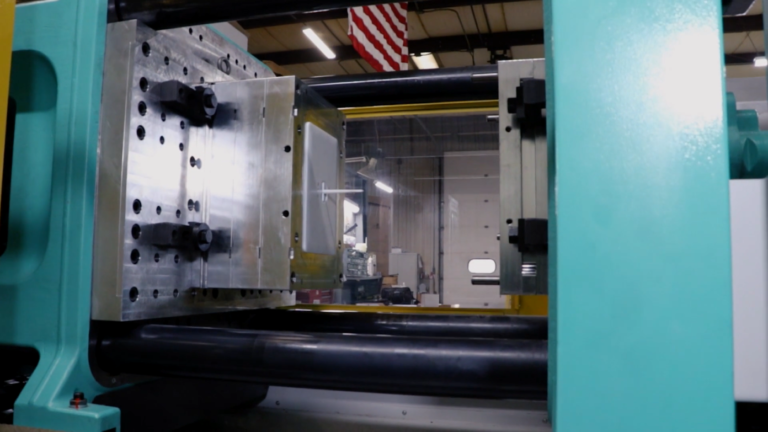

At Wepco Plastics, we specialize in precision injection molding, leveraging cutting-edge technology and decades of expertise to deliver exceptional results. Our injection molding process enables the seamless production of custom prototypes and functional manufactured components with lead times as fast as 5 days.

With meticulous attention to material behaviors, tool dynamics, and process nuances, we ensure every component we produce epitomizes quality and precision. Whether it’s fine-tuned components for medical devices or precise parts for electrical applications, our versatile range of injection molding machines and tooling options accommodates diverse part sizes and intricacies.

Committed to excellence, we continually invest in the latest machinery and advancements to stay at the forefront of the industry, empowering us to meet evolving market needs and exceed client expectations. Experience the transformative power of Wepco Plastics’ injection molding solutions, where innovation meets craftsmanship.

Our Material List

Explore our extensive array of over 100 thermoplastic elastomer resins. This list is not exhaustive, and we are available to discuss resin substitutes as needed. Please reach out to us for further assistance.

- ABS

- ABS/PC Blends

- Acetal

- Acetal Homopolymer

- Acrylic

- HIPS

- HDPE

- LDPE

- Nylon

- PBT

- PC/PBT

- PET

- PE/HIPS

- Polycarbonate

- Polyethylene

- Polypropylene

- Polystyrene

- PPE/PS

- PPSU

- TPU

- TPV

CAPACITY

Explore our foundational overview outlining our capacity for injection molded parts. We utilize both standard DME MUD inserts (4″x6″ insert up to 13″x20″ T-slot) and stand-alone tool frames, depending on the application. This overview offers insights into our tooling and production capabilities.

| Stand-Alone Tooling | |

|---|---|

| Size | 16.75 in x 23.00 in x 4.00 in |

| Volume | 30 cu in. |

| Depth | 4 in from parting line |

| 13"x20" T-Slot Tooling | |

|---|---|

| Size | 8.50 in x 14.50 in x 2.25 in |

| Volume | 22 cu. in. |

| Depth | 2.25 in from parting line |